DOUBLE SIDED TAPE +WELDING INSTALLATION TECHNIQUES

Do not install any Aceflex sports flooring unless you are certain that the site conditions are qualified with our ground or subfloor’s requirement.

If you have any doubts about the site conditions,please contact directly with Aceflor or Aceflor authorized distributors before starting installation.

1.Requirement of subfloors

The following subfloors can be used for semi looselay installation:

·Assembled screeds

·Screeds or slabs on insulation

·Concrete floors on upper levels

These subfloors must be free from any risk of humidity at the time of installation and life long. This type of installation is recommended for use on upper levels,heated floors,old compact sports flooring,still glued corrrectly.For all other subfloors,please contact us.

·Please clarify the subfloor making sure the removal of any adhesive,paint,plaster etc..

·Tolerance of level difference is within 3mm which measured by a 2 metter rule

·All ground should be no cracks.IF there is cracks or not level,then must fill and level up well.

2.Checking the Materials

Differences of width(tolerances) may exist between the rolls.

It is advisable to check the material for defects before installation.If there are visible defects, you should inform Aceflor before using the material.

When unloading the materials from containers or trucks, take care of packing,especially the surface of flooring.Please roll or move the rolls in the direction that we roll the flooring,not in reverse direction.

Please make sure all rolls stand up in the installation facilities if the venue or subfloors are not ready for the installation.

3.Preparation of Materials

·Venue temperature and all installation should be done under minimum 15 centigrade,maximum 30 centigrade.

·Unroll and lay flatt the rolls for 24 hours along the length of the sports hall or in accordance with a floor plan before installation,let the flooring assimilate the temperature and humidity in the venue. and keeping them in order as the label pasted on the rolls,and leave a gap(1cm) between each rolls.(caution:the lengths should be unrolled starting in the center of the sports hall)

·using a flooring roller will make the material easier to install.

4 Adhering under the edges,at the periphery and infront of access areas or storage areas and on the halfway of the lengths of the rolls

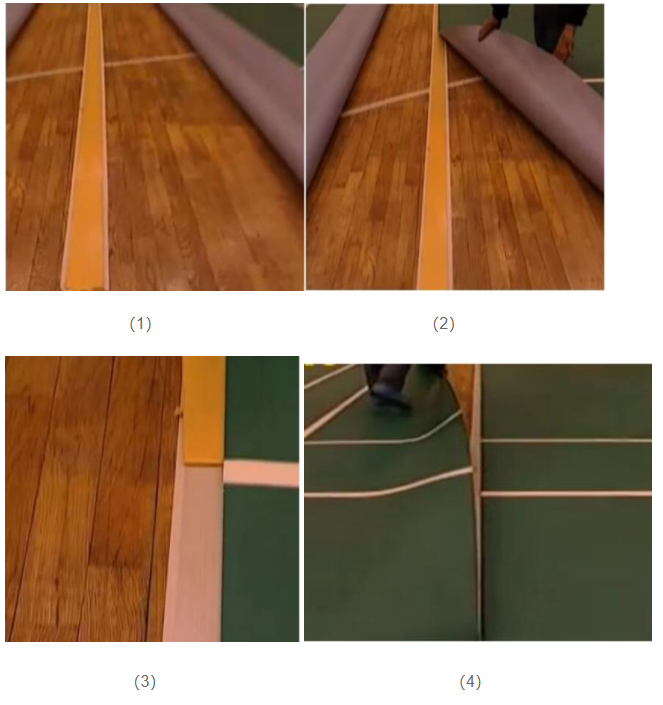

·Hold back two edges of rolls half way(see the photos as below)

·Stick one side of double sided tape on the ground(1).and return two edges of rolls to original position without gap(2).Peel the slip on the other side of tape(3),then stick the joints down the ground tightly(4).

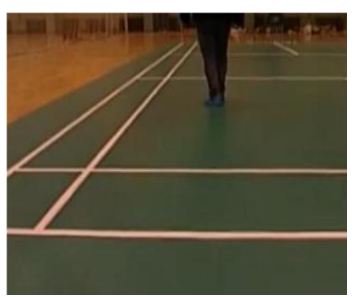

Make sure the floor paste on the ground tightly

·Repeat the process on the following rolls

·Manual roller to make sure all joints are tightly stuck down the ground and there is no bubble or air between the ground and floor whilst applying the lengths.

Note:If it is being put down on a varnished wood strip flooring,check the adhesion proporties before installating.If the subfloor shows advertising logos or stuck-down game lines,they may be damaged. So should be used Acelfor flooring protection papers before sticking double sided tape.

Cautions:

Forbid any traffic or sports playing for 48 hours after laying as well as any furniture movement.

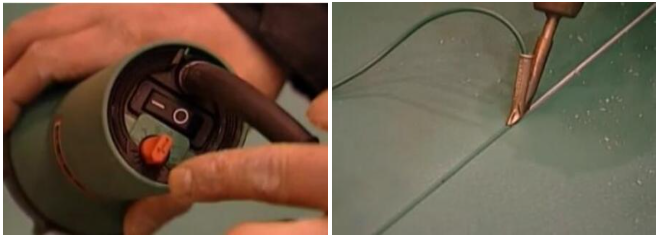

5. Hot welding(12hours after sticking down)

5.1 Grooving: should be test grooving and welding on one small pc of flooring firstly. Make sure the groove depth is at least 1/3 of flooring, Make sure 2/3 diameter of welding rod can be put in the groove,or need groove deeper.grooving the same width on both edges of two rolls(Usually the machine have been set well for the grooving)

Set the grooving roller on the joint

Make sure 2/3 diameter of welding rod can be put in the groove,or need groove deeper.

5.2Welding:Set the temperature mark to 2 firstly for 1 minute then to mark 3 for 1 minute,unitl reach to mark 9.Make sure the temperature is set to 9 marking,almost reach 850-900 degree centigrade.Then pull the welding gun to welding the rod with flooring together.

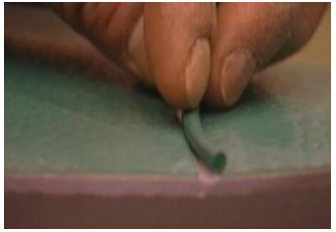

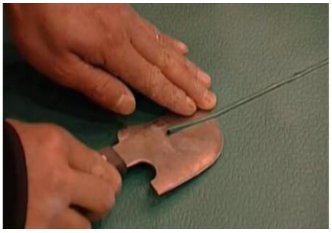

5.3Trimming welding rod: Using the moon blade knife cut the ledge of welding rod to make sure the flooring surface smooth.This must be done when the rod is cold.

Trimming must be done in one pass.

Cleaning work:

Using a damp mop to clean the flooring.confirm there is no water left on the surface.

Other accessories recommend:

Double sided tape: Aceflor double sided tape 10cm with fiber mesh inside

Paint for drawing court line:

It is screen printing ink. Some brands will tell you for pvc flooring court line drawing.

The thinner: main content is Olefin acid,not the nitro.

You will easily to find them in hardware shop or building materials market.

Welding gun: recommended leister 105407